- Geography Location

- Develop History

- Natural Resources & Cultural Resources

- Four Seasons in Pingsi

- Mining Culture

- Indigo Dye Crafts

- Pingsi Commercial District Association

自然人文-藍染技藝

Pingsi grew dye root and dyer's-weed from the late Qing Dynasty and operated an indigo industry with sales to Mainland China. The peak of the indigo industry was in the 1870s. Taiwan’s robust dyeing industry at the time needed large amounts of indigo, so Pingsi became the main indigo supply region in northern Taiwan.

In addition to the dye root and dyer’s-weed being used to make dye, there are also Taiwan flowering cherry, acacia, and sword grass, which are dye raw materials can be relatively easily found in the wild. In recent years, Pingsi Township has carried on the crafts of previous generations and applied them in all kinds of creative products as part of integrated community development. This has led to the reemergence of the development of indigo dye.

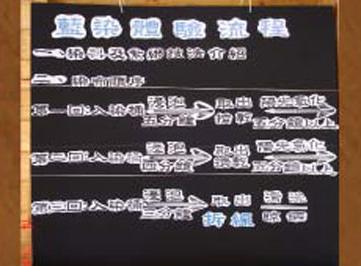

| The Indigo Dyeing Process: | |

| Picking: | Gather the hill indigo. |

| Soaking: | Soak the hill indigo. |

| Making indigo: | Scoop out the decomposed leaves and add lime → stir quickly until the froth becomes tiny bubbles →let the indigo liquid set →wait for indigo liquid to settle →remove the brown waste liquid from the top layer or use canvas as a filter→ get the indigo |

| Preparing the indigo : | Add water, alkali liquid, and enchyma to the indigo to make it turn to a yellow-green dye liquid that can used as dye. |

| Choosing the cloth: | Dye woven fabrics such as cotton, hemp, silk, or wool. |

| Dyeing the cloth: | Place the cloth that has been designed and processed into the indigo liquid vat to soak, lightly press it, heat it to remove the oxidants, and then repeat several times. |

| Cleaning : | Wash the dyed cloth with neutral cleaning solution and hang dry it. |